Yansheng Composite is a professional global supplier of high-performance composite materials, serving customers across industrial, marine, transportation, and sports sectors. Carbon fiber fabric is one of our key product categories, widely selected for projects that require high strength, low weight, and long-term reliability.

Rather than focusing on manufacturing processes, this article highlights real supply reminders, application scenarios, and practical use cases to help engineers, buyers, and project managers better understand how carbon fiber fabric used in real-world projects.

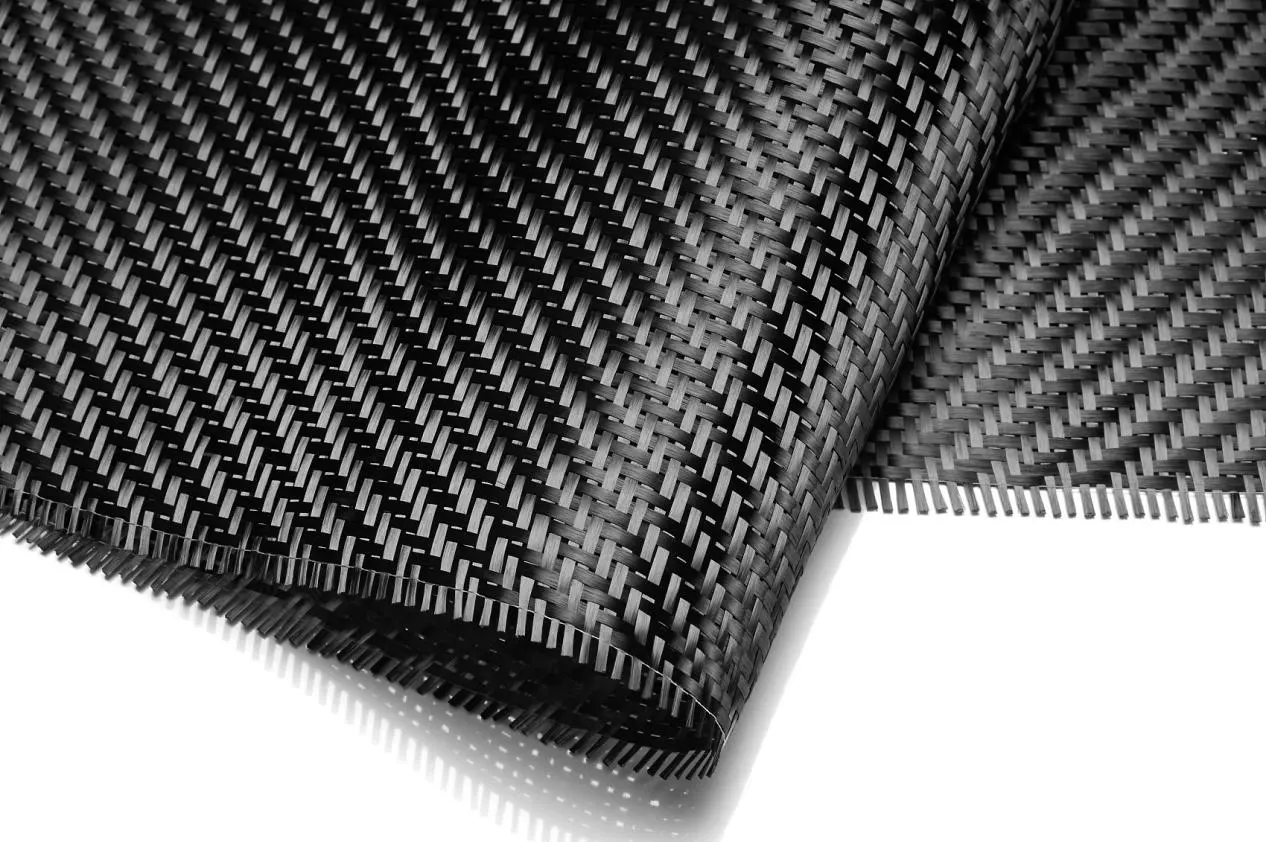

What Is Carbon Fiber Fabric?

Carbon fiber fabric is a woven textile it made from carbon fiber filaments (typically 1K, 3K, 6K, or 12K tow sizes). These fabrics are combined with resin systems such as epoxy, polyester, or vinyl ester to form lightweight yet extremely strong composite structures.

Compared with traditional materials like steel or aluminum, carbon fiber fabric offers:

·Extremely high tensile strength

·Low weight and high stiffness

·Excellent fatigue resistance

·Corrosion and chemical resistance

·Long service life

These advantages make carbon fiber fabric a preferred reinforcement material for advanced composite structures.

Common Types of Carbon Fiber Fabric Available

Through long-term cooperation with composite manufacturers and project users, Yansheng Composite provides a wide range of carbon fiber fabrics to meet different design and performance requirements:

Plain Weave Carbon Fiber Fabric

Balanced structure, easy handling, widely used for structural reinforcement and surface layers.

Twill Weave Carbon Fiber Fabric

Better drapability and visual appearance, commonly used in automotive and sports products.

UD (Unidirectional) Carbon Fiber Fabric

Maximum strength in a single direction, ideal for load-bearing components.

Multiaxial Carbon Fiber Fabric

Designed for complex stress distribution in large structural parts.

Available tow sizes include 1K, 3K, 6K, and 12K, with areal weights ranging from 90 g/m² to 600 g/m².

Key Applications of Carbon Fiber Fabric

1. Industrial Reinforcement & Structural Strengthening

Carbon fiber fabric is widely used to strengthen concrete, steel, and composite structures without adding significant weight.

Application example:

A civil engineering contractor in Southeast Asia sourced 3K plain weave carbon fiber fabric (200 g/m²) from Yansheng Composite for structural reinforcement of industrial floors and beams. The material was applied using epoxy resin to improve load-bearing capacity and extend service life, while minimizing downtime during installation.

2. Automotive & Transportation

Carbon fiber fabric helps reduce vehicle weight, improve fuel efficiency, and increase structural rigidity.

Application example:

An automotive parts manufacturer in Europe uses twill weave carbon fiber fabric from Yansheng Composite to produce interior panels and lightweight body components. Compared with traditional glass fiber solutions, the carbon fiber fabric reduced part weight by over 30% while maintaining excellent surface finish.

3. Marine & Boat Building

Due to its corrosion resistance and fatigue performance, carbon fiber fabric is ideal for marine environments.

Application example:

A boat builder in Australia selected UD and biaxial carbon fiber fabrics supplied by Yansheng Composite for reinforcing hull sections and deck structures. The result was improved stiffness and durability under long-term cyclic loads and harsh marine conditions.

4. Sports & Leisure Equipment

Carbon fiber fabric is commonly used in high-performance sports products where lightweight and strength are critical.

Application example:

A sports equipment manufacturer uses 1K and 3K carbon fiber fabric from Yansheng Composite to produce bicycle components and racket frames. The fabric provides excellent vibration damping and strength consistency, helping improve product performance and user experience.

5. Aerospace & High-Performance Engineering

In aerospace and advanced engineering fields, carbon fiber fabric is valued for precision and reliability.

Application example:

A composite workshop supplying aerospace tooling selected unidirectional carbon fiber fabric from Yansheng Composite for mold reinforcement and structural components, benefiting from stable fiber alignment and consistent mechanical properties.

Why Choose Yansheng Composite?

Customers choose Yansheng Composite as their carbon fiber fabric supplier because we focus on reliability, application matching, and long-term cooperation rather than one-time transactions.

Key reasons include:

·Stable supply and consistent specifications

·Clear technical communication and application understanding

·Flexible order quantities for different project stages

·Experience supporting industrial, marine, and sports applications

·Efficient export handling and international logistics coordination

Our goal is to help customers select the right carbon fiber fabric for the right application, reducing risk and improving overall project efficiency.

Carbon Fiber Fabric for Your Project

Whether you are producing structural components, lightweight parts, or high-performance sports equipment, Yansheng Composite carbon fiber fabric can help you achieve better strength, durability, and weight reduction.

Contact Yansheng Composite today to discuss your application, request technical data, or receive a competitive quotation tailored to your project requirements.